Mouton, Nelda

Business School, North-West University, Potchefstroom, South Africa

Nelda.mouton@nwu.ac.za

https://orcid.org/0000-0001-9897-4775

Britz, Dewalt

Material Planner at Danone, Gauteng, South Africa

Dewalt.britz@gmail.com

https://orcid.org/0009-0002-9972-8132

Ensovoort, volume 46 (2025), number 11: 1

Abstract

This study investigates the development and implementation of green supply chain strategies within the South African dairy manufacturing sector. Adopting a qualitative, interpretivist approach, primary data was collected through semi-structured interviews with professionals at a leading dairy producer. Thematic analysis revealed core themes: key drivers, integration strategies, implementation challenges, and impact outcomes. Sustainability emerged as a strategic imperative, embedded in operational practices and supported by frameworks such as the “Impact Journey”. Integration strategies included energy optimisation, recyclable packaging, supplier collaboration, and digital environmental reporting. Key barriers involved stakeholder misalignment, knowledge gaps, and high upfront investment costs. Despite these challenges, green supply chain initiatives delivered measurable benefits in cost efficiency, operational performance, brand reputation, and carbon emissions reduction. The findings offer practical implications for management and contribute to the growing discourse on sustainability. Recommendations for future research are provided to support adoption of green practices across industries.

Keywords: Green supply chain, sustainability, carbon emissions, South Africa, dairy manufacturing

Introduction and background

The escalating urgency of environmental degradation—manifested through climate change, biodiversity loss, and escalating levels of air and water pollution—has compelled governments, businesses, and consumers to reconsider conventional supply chain paradigms. In response, Green Supply Chain Management (GSCM) has emerged as a critical framework for embedding environmental sustainability into all facets of the supply chain, including product design, material sourcing, production, distribution, and end-of-life management (Srivastava, 2007).

In South Africa, where the manufacturing sector is a vital contributor to economic development and employment, the environmental impact of industrial activity remains significant. The sector accounts for a substantial proportion of the country’s carbon emissions. The South African government’s commitment to achieving net-zero emissions by 2050 further amplifies the urgency for sustainable transformation (UNIDO, 2023). Among manufacturing subsectors, dairy manufacturing is particularly resource-intensive, characterized by high energy consumption, refrigeration demands, and packaging waste (Nguyen et al., 2020). As such, it represents both a challenge and an opportunity for driving impactful green supply chain innovations.

While existing literature underscores the strategic value of green supply chain practices for enhancing environmental performance, competitive positioning, and regulatory compliance (Abdel-Baset et al., 2019; Yildiz Çankaya & Sezen, 2019), empirical research on context-specific applications—particularly within South Africa’s dairy industry—remains limited. Much of the current research focusses on multinational corporations or generalized consumer goods, leaving a notable gap in understanding the operational realities faced by local organizations in emerging economies.

Scope of the study

The article focusses on operational management, specifically green supply chain management within the consumer goods manufacturing industry. The research will be conducted in the Gauteng province (one of nine provinces) with one of South Africa’s leading consumer goods manufacturers.

Research objectives

This research focussed on the following objectives:

- To explore the internal strategies employed by South African dairy manufacturers to implement sustainable supply chain practices.

- To identify the key barriers hindering the adoption of green supply chain strategies in the South African dairy manufacturing sector.

- To examine the primary motivations driving the implementation of sustainable supply chain initiatives among dairy producers.

- To evaluate the impact of these strategies on both environmental sustainability outcomes and operational cost efficiency within dairy manufacturing operations.

Exploring relevant concepts within the manufacturing industry

Organizations may hesitate to adopt green supply chain practices due to perceived risks, uncertain returns, or additional costs. However, a growing body of research has identified various motivations that encourage organizations to adopt more environmentally responsible operations.

Regulatory and Coercive Pressure

Perotti et al. (2013) identified coercive motivators—particularly national and regional environmental regulations—as a primary influence on green supply chain adoption. These are especially significant in sectors dealing with environmentally sensitive materials, where non-compliance can result in legal sanctions and reputational harm.

Wang and Zhang (2023) supported this view, highlighting how government-imposed environmental policies compel organizations to incorporate sustainability into supply chain operations. In the South African dairy industry, frameworks such as the carbon tax, climate action policies, and sector-specific waste regulations intensify this regulatory pressure.

Internal and Strategic Motivations

Internal drivers include organizational commitments to sustainability, efficiency goals, and long-term brand positioning. Perotti et al. (2013) pointed to development budgets and environmental mission alignment as strategic motivators. Wang and Zhang (2023) added that proactive green innovation—investment in environmentally friendly technologies—strongly influences adoption.

For South African dairy manufacturers, internal motivations also stem from the need to manage energy consumption, maintain cold chain efficiency, and align operational goals with broader sustainability objectives.

Societal and Market Expectations

Societal pressure and market forces also encourage the adoption of green supply chain strategies. Perotti et al. (2013) emphasized the influence of consumer environmental awareness, activist campaigns, and media scrutiny. Wang and Zhang (2023) introduced the concepts of normative and mimetic pressures—peer comparisons and stakeholder expectations—as additional motivators.

In the dairy industry, consumer demand for recyclable packaging, low-emission production, and ethically sourced ingredients has become a powerful force behind sustainability-focussed change.

Green supply chain management strategies

To address environmental concerns, companies deploy green strategies across multiple supply chain functions, from sourcing and manufacturing to distribution and disposal. These can vary from conceptual frameworks and various implication techniques:

Conceptual Frameworks and Core Practices

Chin et al. (2015) proposed a framework linking green procurement, manufacturing, logistics, and distribution to improved sustainability outcomes. Hervani et al. (2005) and Srivastava (2007) emphasized practices such as green design and reverse logistics. Yildiz Çankaya and Sezen (2019) extended this by highlighting green marketing as an essential component.

These models are highly relevant to dairy operations, where high energy use and packaging waste are primary environmental concerns.

Practical Implementation Techniques

Agility (2021) outlined six key green supply chain practices:

- Green purchasing: ethical supplier selection and sustainable sourcing.

- Green manufacturing: reducing emissions and increasing energy efficiency.

- Green packaging: using recyclable and biodegradable materials.

- Green warehousing: minimizing energy consumption and waste.

- Green transportation: route optimisation and use of cleaner fuels.

- Life-cycle management: designing products with end-of-life sustainability in mind.

South African dairy manufacturers have begun implementing such practices through investments in solar-powered warehousing, biodegradable packaging materials, and route-optimized cold-chain logistics.

Empirical Evidence of Strategy Adoption

Martins et al. (2019), in their study of Brazilian corporate sustainability disclosures, found that supplier collaboration, route planning, and packaging reduction were the most widely adopted strategies. These findings are transferable to South Africa’s dairy manufacturing context, where companies face similar pressures and resource constraints.

Barriers of implementing green supply chain practices

The implementation of green supply chain strategies remains constrained by a range of internal and external barriers.

Internal Barriers

Perotti et al. (2013), and Hebaz and Oulfarsi (2021) identified internal barriers such as high initial investment costs, limited technical expertise, and difficulties in quantifying the return on sustainability investments. Organizational resistance to change and fragmented leadership also impede progress.

In South African dairy manufacturing, these challenges are compounded by ageing infrastructure and limited access to advanced sustainability technologies.

External Barriers

Organizations also face external constraints, including insufficient supplier capacity, inconsistent regulatory enforcement, and weak consumer demand for sustainable products. Hebaz and Oulfarsi (2021) noted that unclear or poorly enforced environmental regulations undermine the effectiveness of green supply chain initiatives. Adebayo et al. (2024) suggested companies mitigate these challenges through capacity-building and closer alignment with national policy frameworks.

Dairy manufacturers often face difficulties sourcing certified green materials—especially in rural supply networks—and encounter consumer price sensitivity that hampers demand for premium sustainable products.

Balancing Costs and Long-Term Gains

Adebayo et al. (2024) and Esan et al. (2024) argued that while green initiatives may incur high short-term costs, they offer long-term economic benefits through energy savings, efficiency improvements, and waste reduction. This positions sustainability not as a cost burden, but as a potential source of value creation.

In dairy manufacturing—where refrigeration, pasteurization, and packaging dominate operating costs—sustainability investments can support both environmental and economic performance goals.

Research methodology

This study employed a qualitative empirical design to examine the integration of sustainable supply chain strategies within the South African dairy manufacturing sector. A case study approach was adopted, focussing on a single leading dairy manufacturer based in Gauteng province. Primary data was collected through semi-structured interviews with staff involved in both operational and strategic supply chain functions. This methodological design enabled an in-depth exploration of how green strategies are conceptualized, operationalized, and evaluated in a real-world organizational context.

The empirical approach was chosen for its capacity to generate rich, contextualized insights into the motivations, challenges, and impacts associated with sustainability transitions in a high-emission industry. Beyond cataloguing specific practices, the research sought to uncover organizational mindsets, stakeholder dynamics, and performance metrics associated with green supply chain adoption. In doing so, the study contributes to both the theoretical discourse on sustainability integration and the practical advancement of environmental performance in emerging market supply chains.

Research paradigm

The study is situated within an interpretivist paradigm, which emphasizes the subjective construction of meaning and the importance of social context in shaping organizational behaviour. Interpretivism allowed the researcher to engage deeply with participants’ perspectives, recognizing the influence of organizational culture, regulatory environments, and market pressures. In contrast to positivist approaches that seek generalizable findings, this paradigm enabled the development of nuanced, context-specific insights that reflect the complex realities of strategic alignment and decision-making.

Research approach

The study followed an inductive, qualitative research approach in alignment with the interpretivist worldview. Data collection and analysis occurred in an iterative manner, allowing patterns and themes to emerge organically from the data rather than being predetermined. This approach proved particularly effective in capturing the multidimensional nature of green supply chain integration, including its drivers, operational execution, and measurable outcomes.

A cross-sectional time frame was employed, with interviews conducted during a defined period in 2024. This design provided a temporal snapshot of sustainability practices during a key phase in the organization’s transformation journey, highlighting both progress and persistent constraints.

Measurement instrument design

Semi-structured interviews were selected as the primary data collection tool due to their flexibility and capacity to elicit detailed responses. An interview guide was developed to cover the key thematic areas: sustainability motivations, implementation strategies, barriers, stakeholder involvement, and outcome evaluation. The format allowed for open-ended responses and follow-up questions, facilitating the exploration of deeper organizational nuances.

Sampling strategy and participant profile

A purposive sampling strategy was applied to identify participants with direct involvement in supply chain-related sustainability initiatives. This ensured that the data would be grounded in relevant operational and strategic perspectives. The final participant group included professionals from diverse functions within the organization, as summarised below:

- Participant 1 – Industrial: Performance and Project Management

- Participant 2 – Operations Logistics: Distribution Coordinator

- Participant 3 – Cycles and Procurement: Direct Spend Manager

- Participant 4 – Operations Logistics: Loss Control and Logistics Manager

- Participant 5 – Research and Innovation: Packaging Engineer

- Participant 6 – Operations Logistics: Logistics Project Manager

This sampling approach enhanced the credibility and depth of the findings by incorporating a range of perspectives across interrelated supply chain roles within the same organizational ecosystem.

Data analysis

This study applied a structured thematic analysis approach to examine the qualitative interview data, a method well-suited for identifying recurring patterns of meaning across complex datasets (Clarke & Braun, 2015). Thematic analysis enabled the researcher to interpret subjective experiences, trace organizational narratives, and extract operational insights, thereby enriching the depth and credibility of the findings.

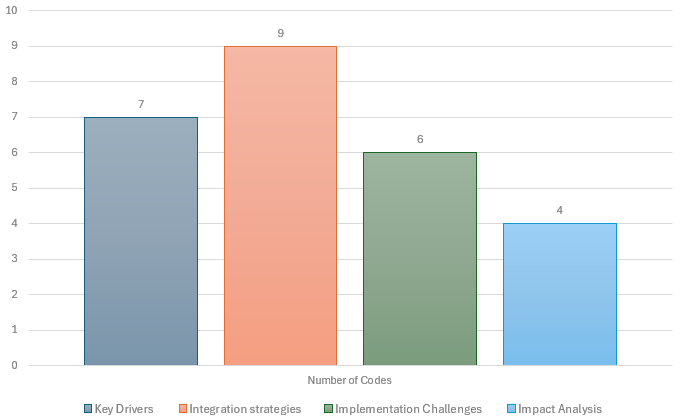

To support systematic data management and coding, the analysis was conducted using Atlas.ti software. The tool facilitated the organization, clustering, and refinement of codes, ensuring analytical rigour and consistency across interviews. The initial coding process generated 1 772 individual codes, which were progressively refined into 26 analytical categories. These categories were further consolidated into four overarching themes, as illustrated in Figure 1.

The four emergent themes each represent a core dimension of green supply chain strategy implementation within the case organization and include:

- Key Drivers – Underlying motivations and pressures (internal and external) prompting sustainability adoption.

- Integration Strategies – Operational tactics and organizational mechanisms used to implement green supply chain practices.

- Implementation Challenges – Internal and external barriers to effective execution of sustainability initiatives.

- Impact Analysis – Observable outcomes relating to cost efficiency, operational performance, brand reputation, and carbon emissions.

The coding process followed an iterative cycle, involving constant comparison and thematic refinement. Initial codes were reviewed, consolidated, and grouped into broader categories to ensure they were closely aligned with the data. This inductive approach grounded the final themes in participants’ actual responses and reflected real-world operational contexts.

To ensure credibility and trustworthiness, the themes were not only data-driven but also triangulated with insights from existing literature. This alignment provided both contextual richness and theoretical grounding, supporting the development of visual outputs and thematic tables in the findings section.

Each theme captures a critical dimension of green supply chain implementation. These are:

Key Drivers – Underlying motivations and pressures (internal and external) prompting strategic sustainability adoption.

Integration Strategies – Operational tactics used to implement green supply chain practices.

Implementation Challenges – Organizational and systemic barriers.

Impact Analysis – Observed effects on cost efficiency, operational performance, brand reputation, and carbon emissions.

The analysis process included iterative coding cycles, where initial codes were reviewed and regrouped into broader categories. The iterative nature of the analysis ensured that the final themes were grounded in participant responses and reflective of real-world practices.To ensure credibility, the themes and categories were not only data-driven but also aligned with existing literature, enabling both contextual depth and theoretical grounding.

In the next section the themes and categorized will be analysed and will be followed by a discussion of each theme.

Theme 1: Key drivers for green supply chain implementation

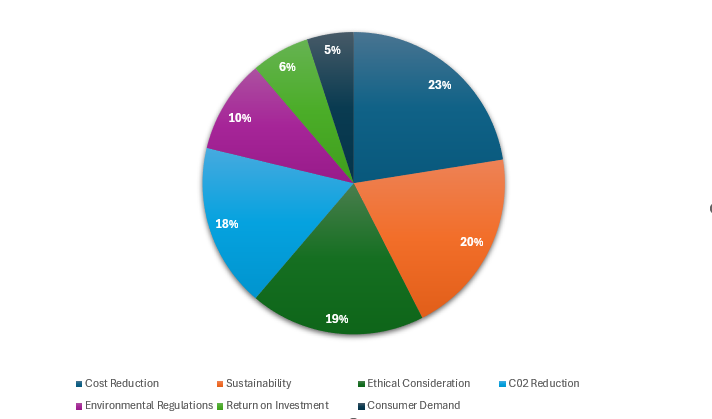

Table 1 illustrates the thematic analysis of Theme 1 and revealed the seven key drivers (categories) motivating the adoption of green supply chain practices within the case organization:

Table 1: Key drivers and descriptions

| Theme 1: Key Driver | Description |

| Cost Reduction | The primary motivation for implementing green supply chain strategies is the cost-benefit these strategies have for operations. |

| Sustainability | This represents using resources responsibly, not wasting them and reserving them for future use. |

| Ethical Consideration | The organization’s motivations stem from corporate responsibility. Implementing green supply chain strategies motivates the organization to act ethically and morally. |

| C02 Reduction | Reducing carbon emissions is a critical motivator for implementing a strategy. |

| Environmental Regulations | This is an external motivator. It focusses on institutional pressure to implement less harmful practices to the environment. |

| Return on Investment | The primary motivator for implementing green supply chain strategies is the return on investment the organization can benefit from. |

| Consumer Demand | This refers to consumer pressure motivating the organization to implement green supply chain strategies. |

These drivers emerged consistently across participant interviews and collectively accounted for 79% of all coded references within the “drivers” category. Among them, cost reduction was the most frequently cited, particularly in connection with ROI assessments and business case evaluations.

Participant feedback is illustrated per category in the figure below.

Specific responses that emerged were:

Participant 1: “The organization has a green payback… When you’re doing a project, you’ll do a cost-benefit sort of analysis… We are looking at a few metrics.”

Participant 2: “An organization must have a mission to be sustainable… 10 to 20 years from now for the next generation.”

Participant 3: “We ensure all our supplies are registered on SEDEX… They share updates on their progress in sustainability.”

Participant 4: “There is a target towards 2030 to reduce carbon emissions… to use bio-fossils for packaging and so forth.”

Discussion

These insights from participants highlight the organization’s multifaceted motivation for adopting green supply chain strategies. While internal ethical frameworks and long-term sustainability goals shape strategic orientation, economic feasibility remains the primary lens through which projects are approved and prioritized.

The data affirm that economic viability is the dominant driver of sustainability adoption, supporting prior findings in the literature (Perotti et al., 2013; Wang & Zhang, 2023). Interviewees emphasized that projects are only pursued if they make financial sense—regardless of their potential environmental benefits. This further substantiates a pragmatic, ROI-driven mindset, where sustainability is integrated as long as it aligns with cost-saving imperatives.

Nonetheless, the prominence of sustainability and ethical considerations indicates a growing organizational commitment to corporate social responsibility. The use of tools such as SEDEX for supplier monitoring, and the alignment of practices with the company’s global “Impact Journey” framework, suggest an embedded ethical culture and a shift towards long-term strategic alignment with global sustainability trends.

External regulatory pressures and consumer demand were also mentioned, though less frequently, reinforcing institutional theory perspectives—where coercive (regulatory) and mimetic (peer/market-driven) forces shape organizational behaviour. While these forces support sustainability adoption, they appear to function more as reinforcing factors than primary decision-making triggers.

Theme 2: Green supply chain integration strategies

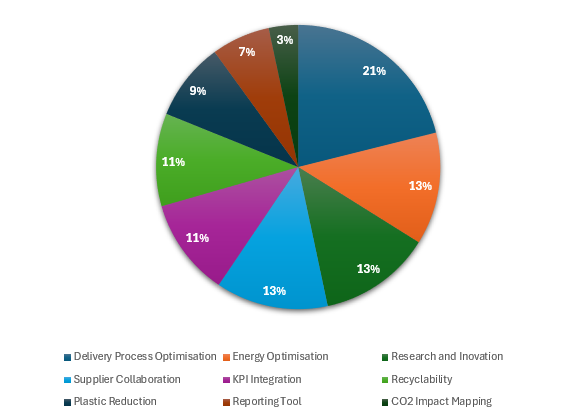

This theme focussed on integration strategies where 9 distinct categories were identified as can be seen in Table 2.

Table 2: Integration Strategy and Description

| Theme 2: Integration Strategy | Description |

| Delivery Process Optimisation | The process of delivering products and materials at a minimum cost and impact on the environment. |

| Energy Optimization | Implementation of strategies to reduce or produce more sustainable energy for operation purposes. |

| Research and Innovation | Redesign formulations, packaging, and secondary materials to have less of an impact on the environment. |

| Supplier Collaboration | Supplier selection and collaboration strategy to ensure materials used are ethically and sustainably sourced. |

| KPI Integration | This refers to the organization’s KPI integration strategy, “impact journey,” which focusses on the environment, people, and health. |

| Recyclability | A strategy that ensures materials used in organizations’ products are recyclable. |

| Plastic Reduction | This strategy focusses on reducing the amount of plastic used in packaging materials. |

| Reporting Tool | This is the system the organization uses to report and interpret data regarding environmental impact. |

| CO2 Impact Mapping | This strategy involves mapping C02’s impact to understand where the organization can minimize its impact. |

These strategies collectively represent a holistic approach to embedding sustainability across the supply chain, with the top six accounting for 81% of strategy mentions (see Figure 3).

The responses by participants strengthened the importance as can be seen by Participants 3 and 1:

The organization has an energy initiative project focussed on implementing a combined heat and power (CHP) plant (Participant 3). This plant will be implemented at the organization’s factory in South Africa and can generate electricity from various fuel sources (Participant 3). This will allow the organization to use coal or natural gas to produce electricity. Participant 1 stated that the CHP project would lead to an estimated 50% carbon emission reduction at the organization’s factory. This also includes an ammonia compressor upgrade. This will allow for a more efficient cooling system in the factory using less electrical energy (Participant 1).

Participant 1 also explained that the next step after the CHP implementation in 2024 will be to look at a 100% biogas project. This will allow the factory to be a net zero production facility from an energy perspective and completely independent from ESKOM (the electricity provider in South Africa).

Participant 3 also pointed out that solar energy was installed for all the third-party warehousing. This is mainly due to the organization operating in the dairy industry, which requires a warehouse temperature between two and seven degrees Celsius to ensure the cold chain. The solar project allowed efficient and cost-effective running of chillers to maintain the optimal temperature.

Discussion

The findings indicate that the organization is actively implementing tactical and strategic initiatives that span transportation, warehousing, packaging, and energy sourcing. Delivery optimization—reducing delivery frequency and improving pallet use—is the most prevalent and is clearly aligned with both cost-efficiency and CO₂ emission goals.

Energy projects like the CHP and solar warehousing initiatives signify long-term transformation. They not only reduce reliance on the national grid (Eskom) but also address carbon footprint challenges. This is consistent with Hervani et al. (2005) and Chin et al. (2015), who emphasized green logistics and energy use in sustainable supply chains.

Packaging innovation (e.g., light-weighting, recyclability) and supplier engagement (via SEDEX and Polyco) reflect downstream integration and extended producer responsibility. The KPI framework—particularly the Impact Journey—demonstrates institutionalization of sustainability through structured measurement, echoing frameworks proposed by Srivastava (2007) and, Yildiz Çankaya Sezen (2019).

All participants referred to the organization’s delivery process optimization strategy, which focusses on reducing carbon dioxide emissions in transport (Participant 6). This Strategy involves the following:

Optimizing delivery loads to the maximum capacity to reduce the number of loads delivered to clients weekly in the case of direct deliveries. This is done by prompting clients to order all they need on a single day. This increases order sizes and ensures full load utilization and less frequent deliveries. Participant 6 stated that this reduced deliveries to individual clients from four to a maximum of two times a week.

The second part of this strategy includes re-examining how the product is packed on pallets. This aims to ensure pallets are utilized to the fullest, increasing load utilization. Participant 6 also focused on primary deliveries between the factory and the organization’s distribution centres. By optimizing pallet utilization, warehouse movements within distribution centres were decreased as more products could physically be moved from one point to another.

The above strategies have precise cost and efficiency benefits. Reducing the movements needed to supply consumers and optimizing warehouse movements positively impact reducing carbon emissions.

The organization has an energy initiative project focussed on implementing a combined heat and power (CHP) plant (Participant 3). This plant will be implemented at the organization’s factory in South Africa and can generate electricity from various fuel sources (Participant 3). This will allow the organization to use coal or natural gas to produce electricity. Participant 1 stated that the CHP project would lead to an estimated 50% carbon emission reduction at the organization’s factory. This also includes an ammonia compressor upgrade. This will allow for a more efficient cooling system in the factory using less electrical energy (Participant 1).

Participant 1 also explained that the next step after the CHP implementation in 2024 will be to look at a 100% biogas project. This will allow the factory to be a net zero production facility from an energy perspective and completely independent from ESKOM.

Participant 3 also pointed out that solar energy was installed for all the third-party warehousing. This is mainly due to the organization operating in the dairy industry, which requires a warehouse temperature between two and seven degrees Celsius to ensure the cold chain. The solar project allowed efficient and cost-effective running of chillers to maintain the optimal temperature.

The organization has a dedicated research and innovation team that focusses on launching new products. The team also focusses on redesigning packaging for cost reduction and the impact journey pillars (Health, People, and the environment). Participant 5 is part of this team and explained that the organization has the tools to design more recyclable products. They pointed out a project called Bubbles.

This project is currently moving from standard compact plastic sheets to foam sheeting. Participant 5 explained that this would lead to better yields from the supplier, reducing cost and plastic reduction, making it more environmentally friendly.

Participant 3 stated that organizations also focus on light-weighting as a material design strategy. This positively affects cost reduction and the environment as fewer harmful materials are used. Participant 5 gave a practical example of the organization’s project implementation to reduce the number of beards used in their secondary packaging. This has led to an initiative called one-way packaging, where the actual crates are not made from plastic but recyclable corrugated paper. It is designed to last just the time it takes to deliver the product to consumers and then start to deteriorate (Participant 2).

Participant 3 explained that all the organization’s suppliers must be registered on SEDEX. This global organization specialises in data and services related to supply chain sustainability (SEDEX, 2024).

The procurement team conducts quarterly business reviews (QBR) with each supplier. One key aspect of a VAGA analysis is environmental considerations. Suppliers must present an update on environmental projects they must implement (Participant 3). The organization itself is a member of Polyco; therefore, the organization pays fees based on the number of plastic suppliers and the organization’s use (Participant 3). Polyco uses these fees for recycling projects, as mentioned by Participant 3. Supplier collaboration strategies are also closely linked to research and innovation. If the organization redesigns a product or specific materials, the suppliers who supply the material must be reassessed regarding capability and cost.

The KPI integration strategy focusses on the organization’s impact journey strategy. Participant 1 explained that the impact journey is a set of frameworks concentrating on three pillars: people, health, and the environment (Participant 1). Under the environmental pillar, a set of KPIs needs to be met. Participant 1 referred to the innovation map as part of the impact journey. This map includes sustainability factors that need to be tracked and reported on. The participant listed a few essential targets like responsible water usage, deforestation, and recyclability and that action plans are in place to tackle these problems locally.

Participant 3 stated that the impact journey is part of everyone’s KPI in the organization. This is how management on a local and global scale ensures total integration with the three pillars of the impact journey.

Under the research and innovation strategy, the organization designs its products to be more recyclable. However, the organization also plays a significant role in ensuring the materials it uses get recycled. Participant 3 explained that the organization has initiatives at schools to collect empty packaging material. This material that would have been wasted is recycled and made into school desks for the children.

Theme 3: Green supply chain integration strategies

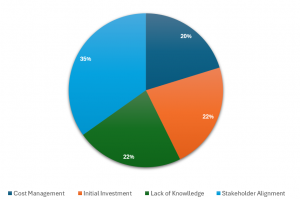

This theme focussed on integration strategies where 4 distinct categories were identified as can be seen in Table 3.

Table 3: Theme Implementation Challenges and Description

| Theme 3: Implementation Challenges | Description |

| Cost Management | This refers to the ongoing cost the organization must ensure when implementing a green supply chain process. |

| Initial Investment | This is the high upfront investment an organization must incur to implement a green supply chain process or strategy. |

| Lack of Knowledge | The lack of understanding, skill and knowledge creates challenges when implementing green supply chain processes or strategies. |

| Stakeholder Alignment | Ensuring internal and external stakeholder buy-in when implementing green supply chain strategies or processes is challenging. |

The table emphasis the 4 main categories with descriptions. Figure 4 provides more insight on the impact of each category.

The most frequently reported impacts were related to cost and operational efficiencies, driven by initiatives such as delivery and pallet optimization, and the use of alternative energy sources. Participants also emphasized reputational benefits linked to visible green branding and community-focussed sustainability efforts. The respondents mentioned:

Participant 2: “Green supply chain… cost saving goes hand in hand.”

Participant 6: “We saw firsthand that sustainability was directly linked to our efficiency.”

Participant 3: “When you adopt green practices… it enhances your reputation.”

Discussion

Stakeholder alignment regarding green supply chain initiatives is a significant roadblock for the organization’s employees. Participant 1 mentioned that, despite the known energy improvement and carbon emission reduction, it took three years to get the signoff and the contract in place for the CHP project.

Participant 3 pointed to the challenge of conflicting with KPIs regarding the impact journey strategy. It was explained that the procurement KPI is to source locally, but they also have a cost-saving KPI, and in some cases, it is significantly more cost-effective to import. If procurement chooses a supplier from abroad with longer lead times, the material planning team pushes back. They don’t want to keep high buffers; their main KPIs are capital management and stock turnover. Participant 5 questioned if the organization focussed on sustainability, as most projects from the cycles and procurement department focus on cost initiatives.

Participant 4 alluded to the difficulty of aligning the clients with the new delivery strategy. The participant stated that, at first, the clients hesitated to take a maximum of two deliveries a week. After the trial period, it was easy to change order patterns as the clients started to see the benefits.

Participant 5 stated that they needed to run trails for some lightweight caps. This big plastic and cost initiative focusses on the organization’s multi-grain offering cap. However, due to the high volume of the product and the planning team needing the capacity to service the market, no time can be allocated for the trials.

Participant 4 identified the lack of expertise and knowledge in South Africa as the main challenge. There is still much to learn when designing products and packaging materials and discovering alternatives. Participant 5 explained that lightweight strategies can only reduce the amount of plastic used. The organization is reducing the amount of plastic they use in their materials but cannot altogether remove it. This is because they have not found a solution to provide the same characteristics for the organization’s products.

Participant 2 explained that green supply chain initiatives can be expensive, regardless of the long-term operational cost savings. This is also supported by Participant 3, stating that green initiatives implementation comes with significant upfront investments. Participant 4 took a deep dive into the transport sector and electric vehicles. It was explained that there are currently 3500 hauliers actively operating in South Africa. Each haulier owns between 15 to 100 trucks. The participant stated it would take a significant investment to transition to electric vehicles in the country. The participant also explained that there is a lack of infrastructure within the country regarding electric charging stations and that this will not be viable currently.

Participant 1 stated that organizations still need to make a profit and that the market price is essential to remain competitive. Therefore, initiatives cannot add more cost to the supply chain. Participant 5 stated that a project from one of the organization’s suppliers is to supply a lighter cap. The challenge comes with the colour; most of the market only uses a white or black cup, but the organization’s cap for this product and brand needs to be blue. Due to this requirement, the lightweight cap will be more expensive than the current cap.

Theme 4: Green supply impact analysis

This theme focussed on Green Supply Impact Analysis strategies where 4 categories were identified as can be seen in Table 4.

Table 4: Impact Analysis and description

| Theme 4: Impact Analysis | Description |

| C02 Impact Reduction | Green supply chain processes had a positive impact on C02 emissions. |

| Cost Efficiency | Green supply chain processes had a cost-reduction effect. |

| Efficiency Improvements | Green supply chain processes have improved operational efficiencies. |

| Reputation Enhancement | Implementing green supply chain strategies positively impacted the organization’s reputation. |

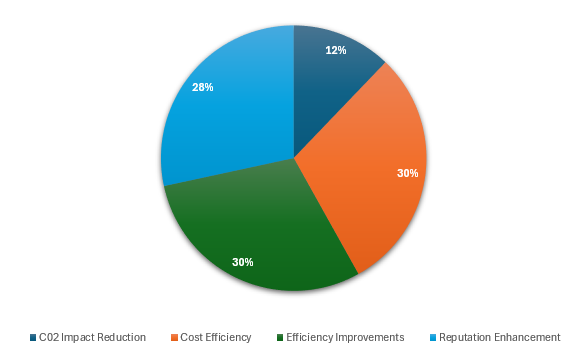

Figure 5 illustrates the percentage weight of each category under the impact analysis theme. Cost efficiency and efficiency improvement came in equal at 30% each. Reputation enhancement is 28%, and C02 reduction is 12%.

Discussion

Several projects were identified as delivering both economic and environmental benefits. The CHP plant and solar installations reduced energy costs while improving reliability and performance. Similarly, delivery frequency reductions and load optimization led to lower fuel and handling costs and improved warehouse efficiency.

Participant 1: “We’ve never done a pure green project. Every project must make business sense and also have a positive green impact.”

Participant 4: “Reducing loads and optimizing pallet configurations saved the business money and boosted productivity.”

Participant 5: “The Bubbles project reduced plastic usage while also lowering material costs.”

Participants frequently referenced the brand image uplift resulting from green initiatives. Examples include recyclable labelling, community-based recycling programmes, and visibility of green KPIs throughout the organization.

Some of the participants reflected as follows:

Participant 3: “We have the recycle logo on all our products… it shows customers we care about the environment.”

Participant 6: “These projects create a ripple effect internally… employees are proud to work here.”

The data clearly demonstrate that green supply chain initiatives generate both tangible and intangible value. The dual emphasis on cost and efficiency challenges the traditional view of sustainability as a cost burden, reinforcing conclusions by Adebayo et al. (2024) and Esan et al. (2024) that sustainability is a value creation tool.

While CO₂ reduction accounted for a smaller portion of reported impacts, it remains a critical metric—particularly given South Africa’s 2050 net-zero commitment. Projects like the CHP plant, the biogas plan, and cold chain optimization via solar cooling contribute directly to measurable emission reductions.

Reputational gains emerged as a powerful motivator, particularly in consumer-facing branding and school outreach programmes. These efforts not only elevate the brand but also foster internal engagement and employee morale, strengthening the link between corporate values and operational behaviour.

The findings further support the idea that successful sustainability integration requires more than compliance—it demands strategic alignment, cross-functional collaboration, and institutionalisation through metrics and culture (as exemplified by the Impact Journey framework).

Recommendations

Based on the findings, the following recommendations are proposed for South African dairy manufacturers and similar goods manufacturing companies:

- Prioritise Cost-Effective Sustainability Projects

Focus on initiatives with dual environmental and financial returns—such as delivery optimisation and energy efficiency. - Strengthen Stakeholder Alignment Mechanisms

Embed sustainability KPIs across departments and improve internal communication to reduce misalignment. - Invest in Capability Development

Close knowledge gaps in materials innovation and green logistics through training and external partnerships. - Pilot and Scale Gradually

Start with small trials (e.g., lightweight packaging) and involve clients early to build buy-in and reduce resistance. - Leverage Industry Collaboration and Certifications

Maximise platforms like SEDEX and Polyco to verify supplier sustainability and encourage broader adoption. - Institutionalise Sustainability through Metrics and Culture

Sustain momentum using structured frameworks like the Impact Journey. Celebrate and communicate achievements internally and externally.

Implications for management

Based on the empirical evidence, several targeted recommendations emerge for managers seeking to enhance the integration and effectiveness of green supply chain strategies in high-impact industries like dairy manufacturing:

1. Formalise Green Business Case Evaluation Frameworks

The study revealed that projects were only approved if they offered both environmental and financial benefits. Managers should formalise the use of dual-criteria business case templates that include both ROI and “green payback” metrics—such as carbon cost equivalence or lifecycle emissions offset. This structured approach can institutionalise sustainable decision-making and reduce subjective barriers in project approval processes.

2. Incorporate Sustainability Metrics into Client Relationship Management

Delivery optimisation efforts were hampered by client resistance to reduced delivery frequencies. Managers should consider incorporating sustainability-linked service agreements with clients, highlighting shared environmental benefits such as carbon savings from consolidated orders. This positions clients as co-owners of green initiatives, fostering alignment and reducing friction during implementation.

3. Create a Dedicated Green Supply Chain Task Force

While the organization had strong operational leadership, cross-functional misalignment emerged as a barrier. Management should establish a dedicated task force or sustainability steering committee that includes representatives from procurement, operations, finance, R&D, and marketing. This team would oversee project alignment, budget justification, and KPI integration—ensuring unified direction across departments.

4. Embed Trial Capacity into Operational Planning

Green innovations such as lightweight packaging were delayed due to a lack of trial capacity. Managers should embed dedicated R&D testing windows within production and logistics schedules, enabling timely experimentation and innovation without disrupting core operations. This requires minor resource reallocation but can significantly accelerate green product rollouts.

5. Institutionalize Supplier Co-Development Platforms

Supplier sustainability was found to be reactive rather than collaborative. Managers should create formal co-development platforms or “innovation hubs” with suppliers, focussed on joint material design, recyclability improvements, and waste reduction. These platforms foster early-stage collaboration, shifting suppliers from compliance enforcers to innovation partners.

6. Implement Localized Impact Mechanisms

The school recycling initiative enhanced employee pride and brand perception, yet such success stories were not consistently leveraged. Managers should develop internal communication strategies—such as visual dashboards, recognition programs, or employee spotlights—to amplify local sustainability success and encourage cultural buy-in.

By taking these targeted actions, managers can move beyond compliance and surface-level sustainability practices toward a strategically embedded, innovation-led green supply chain model. These implications are especially relevant for organizations operating in resource-intensive sectors and navigating the complexities of emerging market constraints.

Limitations of the study

While this study offers valuable insights into the implementation of green supply chain strategies within the South African dairy manufacturing sector, several limitations should be acknowledged:

- Single-case focus:

The research was conducted within a single dairy manufacturing firm. While this case-based approach allowed for in-depth exploration and contextual richness, it limits the generalisability of the findings to other sectors or organizational contexts. - Sample size and participant scope:

The use of purposive, non-probability sampling and a small sample size (n = 6) constrains the ability to draw sector-wide inferences. Although data saturation was achieved, the perspectives captured may not reflect the full spectrum of experiences. - Cross-sectional design:

The study adopted a cross-sectional research design, with data collected at a single point in time. This limits the capacity to observe how green supply chain strategies evolve over time, especially in response to changing regulatory, technological, or market dynamics. - Functional focus of participants:

Most participants were drawn from operations and supply chain departments. While appropriate for the research objective, the exclusion of other functional areas such as finance, marketing, and human resources may have constrained the analysis of cross-functional influences and enablers of sustainability adoption.

Suggestions for future research

To build on the current findings and address the limitations noted above, future research should include (but not be limited to) broader stakeholder inclusion and comparative studies across multiple organizations and sectors. These future research directions would contribute to a more holistic, scalable, and dynamic understanding of sustainable supply chain management, particularly within emerging market contexts like South Africa.

Conclusion

This study examined the development and implementation of green supply chain strategies within the South African dairy manufacturing sector. Through in-depth insights from professionals across key operational functions, the research highlights that sustainability is not merely a compliance obligation or parallel initiative—it has become a strategic imperative that actively drives innovation, operational efficiency, and long-term competitiveness.

The findings demonstrate that effective green supply chain integration requires more than technical interventions; it demands organizational alignment, leadership commitment, and data-driven decision-making. As global and national sustainability expectations intensify, organizations that embed environmentally responsible practices into their core operations will be best positioned to navigate risks, seize emerging opportunities, and create shared value for stakeholders.

Reference list

Adebayo, S. A., Smith, T. J., & Moyo, N. K. (2024). Aligning corporate sustainability with regulatory compliance in emerging markets. Journal of Sustainable Business, 18(2), 112–130. https://doi.org/10.1016/jsb.2024.02.003

Agility. (2021). Six categories of green supply chain management. Agility Logistics. https://www.agility.com

Braun, V., & Clarke, V. (2015). Thematic analysis. In P. Rohleder & A. Lyons (Eds.), Qualitative research in clinical and health psychology (pp. 95–114). Palgrave Macmillan.

Bryman, A., Bell, E., Hirschsohn, P., dos Santos, A., du Toit, J., Masenge, A., Van Aardt, I., & Wagner, C. (2021). Research methodology: Business and management contexts (2nd ed.). Oxford University Press Southern Africa.

Chin, T. A., Tat, H. H., & Sulaiman, Z. (2015). Green supply chain management, environmental collaboration and sustainability performance. Procedia CIRP, 26, 695–699. https://doi.org/10.1016/j.procir.2014.07.035

Epoh, F. M., & Mafini, C. (2018). Investigating green supply chain management practices in South Africa. South African Journal of Industrial Engineering, 29(2), 96–109. https://doi.org/10.7166/29-2-1986

Epoh, F. M., Mafini, C., & Ndebele, C. (2024). Strategic positioning through green supply chain practices in South African manufacturing organizations. Journal of Cleaner Logistics, 12(1), 44–61.

Esan, A., Chiguvare, Z., & Dlamini, L. (2024). Financial implications of green supply chain initiatives in Sub-Saharan Africa. International Journal of Environmental Management, 36(1), 77–90.

Hervani, A. A., Helms, M. M., & Sarkis, J. (2005). Performance measurement for green supply chain management. Benchmarking: An International Journal, 12(4), 330–353. https://doi.org/10.1108/14635770510609015

Hebaz, K., & Oulfarsi, S. (2021). Barriers to green supply chain management: Empirical evidence from emerging economies. Environment, Development and Sustainability, 23, 14012–14029. https://doi.org/10.1007/s10668-021-01302-3

Hox, J. J., & Boeije, H. R. (2005). Data collection, primary vs. secondary. In K. Kempf-Leonard (Ed.), Encyclopedia of Social Measurement (Vol. 1, pp. 593–599). Elsevier.

Martins, V. W. B., Rampasso, I. S., Anholon, R., Quelhas, O. L. G., & Leal Filho, W. (2019). Knowledge management in the context of sustainability: Literature review and opportunities for future research. Journal of Cleaner Production, 229, 489–500.

Mvubu, M., & Naudé, M. J. A. (2016). Green supply chain management constraints in the South African fast-moving consumer goods industry. Journal of Contemporary Management, 13(1), 599–622.

Perotti, S., Zorzini, M., Cagno, E., & Micheli, G. J. L. (2013). Green supply chain practices and company performance: The case of 3PLs. Journal of Cleaner Production, 39, 93–104. https://doi.org/10.1016/j.jclepro.2012.08.039

Saunders, M., Lewis, P., & Thornhill, A. (2009). Research methods for business students (5th ed.). Pearson Education Limited.

SEDEX. (2024). About SEDEX. https://www.sedex.com

Srivastava, S. K. (2007). Green supply‐chain management: A state‐of‐the‐art literature review. International Journal of Management Reviews, 9(1), 53–80. https://doi.org/10.1111/j.1468-2370.2007.00202.x

Wang, T., & Zhang, X. (2023). Coercive and normative drivers of green supply chain management: A multi-case study in Asia. Sustainable Operations Journal, 11(3), 215–232.

Yildiz Çankaya, S., & Sezen, B. (2019). Effects of green supply chain management practices on sustainability performance. Journal of Manufacturing Technology Management, 30(1), 98–121. https://doi.org/10.1108/JMTM-03-2018-0099